In Part One, we reviewed the importance of wet pressure measurement and explored the first four Greystone devices. Modern HVAC systems increasingly demand more flexible sensing, improved access for maintenance, and better fault detection. In this second part we look at the remaining four product types: GLPS-G, PWGS, PWRD, and PWRG. It also expands on integration, commissioning, lifecycle management, and future trends. Together, these topics help engineers select the right sensing strategy for hydronic systems of all sizes.

GLPS-G Series – Gauge Liquid Pressure Switch

The GLPS-G Series operates like the differential switch but measures gauge pressure instead. It triggers an electrical change when the water pressure rises above or falls below a setpoint. Internally, a metal diaphragm or piston moves under pressure and actuates a micro-switch. This type of device is common in domestic hot water systems, pump sets, and safety interlocks. Furthermore, gauge switches are useful for confirming pressure in sprinkler systems or auxiliary circuits. Because they provide a simple binary signal, they integrate easily into any BMS or control panel.

PWGS Series – Pressure Wet Gauge Stand-Alone

The PWGS Series is a mechanical gauge designed for local pressure indication. It features a dial display connected to a bourdon tube or similar sensing mechanism. When pressure increases, the curved tube straightens slightly and drives the pointer across the scale. Although stand-alone gauges do not output electronic signals, they remain essential for technicians who need instant visual confirmation. Additionally, mechanical gauges work without external power and provide a reliable reference during commissioning. Many engineers place them near pumps, strainers, and key branch points to support diagnostic work.

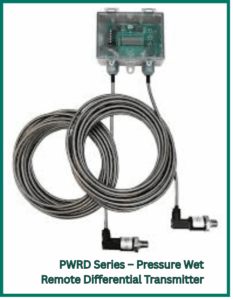

PWRD Series – Pressure Wet Remote Differential Transmitter

The PWRD Series provides differential pressure measurement using remote sensing capsules linked by capillary tubing. This arrangement allows the transmitter body to be mounted away from hot pipes or awkward positions. Each capsule sits close to the measurement point and transmits force through the sealed capillary system. Because of its remote design, the PWRD Series is ideal for high-temperature circuits, large pipe diameters, or locations where vibration is a concern. Moreover, remote sensors simplify maintenance, as the electronics remain accessible in a safe and convenient place.

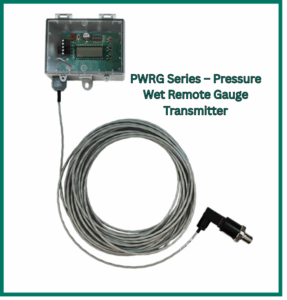

PWRG Series – Pressure Wet Remote Gauge Transmitter

The PWRG Series uses the same remote-capsule concept but measures gauge pressure instead of differential pressure. A single sensing element connects to the transmitter housing via a capillary. This arrangement protects sensitive electronics from heat or water hammer. Furthermore, it allows installers to route the tubing around obstacles while keeping the transmitter on a suitable panel. Applications include boiler loops, condenser water systems, and industrial process circuits. Because remote transmitters avoid direct pipe contact, they often last longer in harsh environments.

Integration and Commissioning in BMS Platforms

Mapping Inputs and Calibrating Ranges

During commissioning, engineers must correctly map pressure inputs into the BMS. Each transmitter provides a scalable 4–20 mA or voltage signal. Therefore, correct range mapping ensures that the displayed readings match the physical system. Furthermore, integrators should apply zero and span checks to maintain accuracy.

Trending and Fault Detection

Once mapped, pressure data supports advanced control. Trending allows operators to identify abnormal pump behaviour or valve hunting. Additionally, many facilities use pressure trends to detect air ingress, blocked strainers, or partial valve failures. These insights reduce downtime through early intervention.

Alarm Schemes and Safety Interlocks

Pressure switches and transmitters form an essential part of HVAC safety logic. For example, low-pressure alarms protect boilers from dry firing. Likewise, differential switches confirm flow across heat exchangers before enabling compressors. Because these interlocks depend on stable sensors, correct installation is crucial.

Maintenance and Lifecycle Considerations

Routine Inspection

Pressure devices require periodic inspection. Although transmitters are stable, technicians should verify readings against mechanical gauges. Furthermore, checking for leaks, damaged capillaries, or blocked impulse lines improves reliability.

Replacement Strategies

Some facilities adopt planned replacement cycles, especially for critical sensors. Others choose condition-based replacement using BMS trends. Because pressure data is vital for plant safety, replacement should follow manufacturer recommendations.

Firmware and Electronic Updates

Modern transmitters may include digital diagnostics or configurable outputs. Therefore, keeping firmware updated enhances stability and long-term accuracy. Regular updates also improve compatibility with newer BMS platforms.

Emerging Trends in Wet Pressure Measurement

Self-Calibrating Sensors

Manufacturers now explore sensors that automatically adjust for drift. This technology reduces maintenance and improves predictability.

Wireless Pressure Devices

Low-power wireless transmitters reduce cabling costs and speed up installation. They are particularly useful in existing buildings with limited access routes.

Edge Intelligence and Local Analytics

Some next-generation transmitters will include local data processing. As a result, devices will detect faults and send alerts before issues escalate.

H3 Predictive Maintenance

BMS platforms increasingly integrate machine learning. Pressure data feeds predictive models that estimate pump wear, detect valve degradation, or forecast pipe fouling.

Practical Recommendations for Engineers and Facility Managers

- Ensure pressure ranges match system operating conditions.

- Use differential measurement for flow-related control.

- Place stand-alone gauges near service points for quick diagnostics.

- Keep transmitters accessible to support calibration.

- Avoid mounting directly on vibrating pipework.

- Use remote-capsule transmitters where temperature is high.

- Trend all pressure signals to support early fault detection.

Greystone’s wet pressure portfolio gives engineers a comprehensive set of tools for managing hydronic systems. Together, transmitters, switches, gauges, and remote sensing solutions provide accurate data for stable control. Furthermore, these devices enhance energy efficiency, reliability, and operational insight. As HVAC systems evolve toward predictive and intelligent operation, precise wet pressure measurement will remain essential.

Automated Control Solutions (ACS) is an importer and distributor of Building Management Systems, Energy Efficient Building Automation Controllers, sensing and control equipment used to control heating, ventilation and air-conditioning (HVAC) systems and field devices such as PICVs.

We understand that our customers want the latest technologies, which is why we have partnered with innovative, dynamic companies like Greystone Energy Systems to ensure that we offer our customers a complete basket of products to cover any Automated Control Solution.

Contact us to discuss these devices or any other products in our extensive ranges.